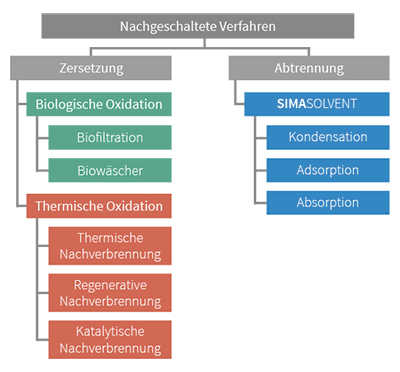

The exhaust air purification processes downstream of paint shops or painting processes can generally be divided into 2 groups. On the one hand, those in which the pollutants are decomposed and thus destroyed and, on the other hand, those processes in which the pollutants are separated and thus removed from the exhaust air unchanged in their chemical structure.

Decomposition of pollutants through metabolism of microorganisms

Biofiltration

Microorganisms are located on a fixed bed which is exposed to the exhaust air.

- Main area of application: Odor reduction

- Suitable for VOC load: up to 1gC/Nm³

- OC separation efficiency: up to 99

- Suitable for exhaust air volume flow: up to 100,000 Nm³/h

ADVANTAGE

- Low energy requirement

- No additional emissions

- High efficiency

DISADVANTAGE

- constant supply of nutrients

- VOCs must be biodegradable

- Conditioning of the scrubbing liquid necessary (pH value)

Bioscrubber

Microorganisms are in an aqueous phase. The VOCs are absorbed into the aqueous phase and can thus be broken down.

- Main area of application: odor reduction

- Suitable for VOC loads: up to 5gC/Nm³

- OC separation efficiency: up to 97

- Suitable for exhaust air volume flow: up to 100,000 Nm³/h

ADVANTAGE

- Low energy requirement

- No additional emissions

- High efficiency

DISADVANTAGE

- constant supply

- VOCs must be biodegradable

- exhaust air conditioning may be necessary before cleaning