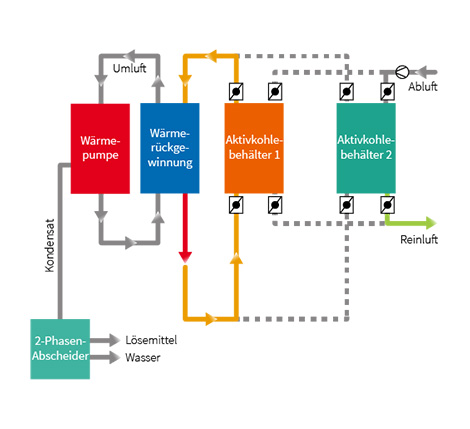

The SimaSolvent® exhaust air purification system is based on the condensation process. The core component of the system is the use of a highly efficient industrial heat pump, which acts as a refrigeration unit. Depending on the application, this can be used either for the direct condensation of volatile organic compounds or in conjunction with an adsorption stage (activated carbon). In contrast to conventional condensation units, the heat energy generated is not released into the environment but can be reused as process heat.

Compared to conventional system technologies, this has the following advantages:

VOC is the abbreviation for volatile organic compounds (volatile organic compounds). This means that these substances evaporate at low temperatures. The point at which a substance is considered a VOC depends on national definitions.