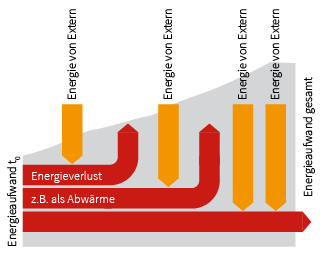

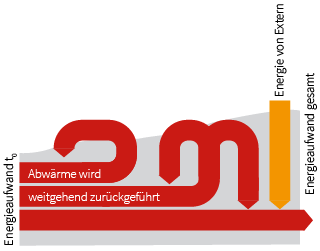

Today, production processes are usually optimized according to the principle of "How can the use of resources (input) be further minimized while maintaining the same yield (output)?". In short: it's all about saving energy. SIMACOVERY® revolutionizes the conventional approach to the term "economic efficiency" in production processes, because SIMACOVERY® makes it possible to recover and reuse energy resources.

Energy in the form of heat is lost unused in almost all industrial processing and production processes. In extreme cases, additional energy even has to be used, for example to cool systems.

The reduction from one heat level to another is called a temperature gradient. Our SIMACOVERY® energy recovery system makes the thermal energy of such a temperature gradient usable again - even with the smallest temperature differences. We analyze the potential of recoverable energy in your company and take this into account when designing the optimum system size for you.

System sizes from 2 kilowatts to 10 megawatts can currently be realized. Operation is extremely cost-effective and our systems pay for themselves within a very short time, depending on the processing quantity and volume.